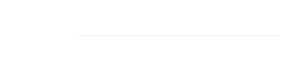

The Role of Ink in Food Packaging Printing

For example, the adhesion test of ink is used to test whether the ink adheres to this material. Testing the temperature resistance of the material, testing whether the material can withstand the temperature of the injection mold in the later stage of injection.

At present, the prints used in in-mold injection moulding are mainly PET, PC and PMMA. Among them, the most widely used PET materials are PET materials. There are many kinds of PET materials on the market, which are produced by regular large factories and from other sources. If the original printing material does not carry out some necessary tests, it will lead to no adhesion between the film material and the ink, resulting in a series of subsequent processes futile. It is suggested that customers of in-mold injection moulding should first test the materials after using different batches of materials for injection moulding.

For example, the adhesion test of ink is used to test whether the ink adheres to this material. Testing the temperature resistance of the material, testing whether the material can withstand the temperature of the injection mold in the later stage of injection.

In fact, the best way to test the adhesion of ink is to use UV ink directly. At present, the common UV ink in the industry must be printed on the materials which are easy to adhere to before it has adhesion. If UV ink has adhesion on this material, solvent-based ink will surely print on the material without any problem.

TAG:

Next:

Related Posts

Food packaging design should be based on market suitability

In general, customers do a design for a variety of reasons. Sometimes in order to launch a brand new product, sometimes in order to update the original product and improve its products, regardless of the design motivation, it is necessary to fully understand the needs of consumers, which requires the design team of this project to have a certain understanding of the market.